Logistics Management Challenges and Resilience within the FMCG Industry

Tagged: Economics & Finance Academic

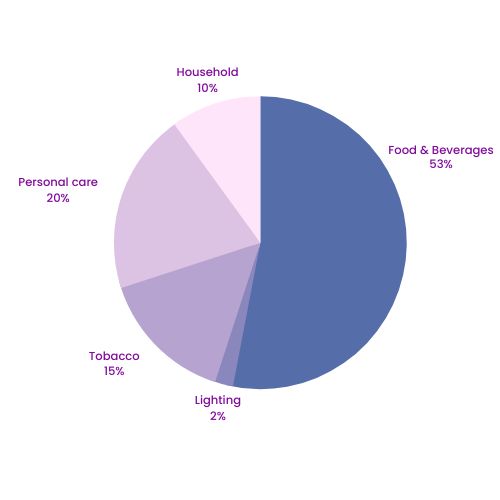

The Fast Moving Consumer Goods (FMCG) provides several products to customers and is prompt and agile. Considering the volume of FMCG products that are consumed by customers, it is understood that this sector is huge. To manage such huge industry sectors, there is a need to have a robust logistics management system. However, with the volume of goods being moved, managing logistics within this industry is wrought with their own set of challenges which this paper attempts to cover. Market segmentation of the FMCG sector in India is outlined through Figure 1.

Figure 1: Market Segmentation of the FMCG Sector

Source: Patil (2016)

Risks

It has been stated by LeMay, Helms, Kimball and McMahon (2017), that the FMCG sector comprises of non-durable goods which consumers require for their daily use. Product attributes would be specific to the industry considering that it would be packaged, nondurable, branded and ready for consumption by the end user. FMCG sector is mainly made up of beverages and packaged foods, spirits and tobacco, household and personal care products. A SWOT analysis executed on the FMCG sector by Karthik and Prasad (2020) did indicate several opportunities, but there existed some threats too. Risks that emerge in the FMCG logistics would result as a part of outcome, vulnerability and threat. Threat would refer to specific and credible information that a component, system or service is being targeted by competitors. Vulnerability would signify weaknesses that may not be inherent to the service, component or system or something that has emerged due to an external agent. Risk within logistics would refer to a situation where the capability and intention of a competitor is in tandem with the scope for harnessing a vulnerability (Dubihlela, Chakabva, & Tengeh, 2021). Risks essentially within FMCG logistics would comprise of the following:

Demand Related Risk

Any probable or actual risk within product flows, cash and information that arises within the logistics network and within the market and the key firm is deemed as demand risk. Any failure that might either is low or high to accurately include; the level of demand is also known as demand related risk. It would comprise of some uncertainties within the mix and product volume (Sharma & Bhat, 2014).

Risks in Procedures

Procedures in this case would refer to the order in which managerial activities and value-addition is executed in an FMCG firm. Procedural risk also refers to any kind of disruption within procedures (Kundu, 2020). FMCG firm’s internal capability for manufacturing and delivering products will be impacted and it arises from scenarios wherein there would be an operational disruption within their manufacturing or operational capability.

Risks in Control

This would mainly pertain to risks that arise from processes, rules, systems and assumptions based on which FMCG firms sustain a robust control over the processes (Simchi Levi, Vassiladis, & Kyratzoglou, 2013). In terms of logistics, it would also take under its ambit; batch sizes, order quantities and stock policies associated with safety. Thus, risks in control include risks that would arise when there is a misapplication or application of such rules.

Risks within Environment

Risks from the environment would pertain to risks associated with external factors from the FMCG firm’s viewpoint. It essentially refers to events that are beyond the firm’s control. It essentially includes any unanticipated uncertainties that might arise from the interaction amongst the environment and the logistics network (Mukhtar, Romli, Abdullateef, & Al-bashiri, 2019). Uncertainties could arise due to several factors like; man-made disasters, natural disasters, accidents and also the current pandemic.

Responding to Threats

For the longest period of time, people who operate within an FMCG logistics network, concentrated mostly on the four ‘V’s (volume, velocity, volatility and visibility), in order to optimize costs on the whole, service quality while focusing on innovation (Shahbaz, RM, Bin, & Rehman, 2017). Over the years, the focus has been to optimize the logistics network in order to reduce costs, inventories while stimulating asset utilization. However, this has resulted in elimination of flexibility and buffers with a view to absorb delays and disruptions. Nevertheless, the onset of the current pandemic has led to several logistic networks to reevaluate their vulnerability from the perspective of global shocks based on their tiered logistics network. Considering that resilience within logistics network have emerged as a key towards a response strategy following the pandemic, emergent business models (such as direct to consumers) for consumer products that have been tagged as niche and the introduction of digital business models like pay-per-use in the FMCG domain have emerged at the fore (EY, 2020).

Agile Forecasting and Planning

Given the current scenario, in order to track the rapidly changing customer preference and any disruptions within the market, agile forecasting and planning would require an effort which is highly collaborative across several functions (working remotely but in a dynamic manner) (Mckinsey & company, 2020). The new normal which has emerged as an outcome of the pandemic does not necessarily drive the forecasting process on the whole. Presence of logistics, labour and raw materials are also of much significance. Furthermore, forecasting is not considered as an exercise that is driven by calendars or work-flows (Dubeauclard, Kubik, & Nagali, 2015). On the contrary, these are facets which emerge from external factors that maybe beyond an FMCG firm’s control. This necessitates the necessity for enunciating varied situations in different ways, identifying requirements, at-risk suppliers and building the capability to develop the expected financial outcomes (Sendil, 2015). Along with these kinds of changes, FMCG organizations are also required to revisit their planning processes which were challenging from the very beginning and demanding, regardless of the scale and scope.

Internet of Things and Industry

Investments in digital transformations are very much the need of the hour for improving logistics networks. This would enable FMCG firm’s to confront any unanticipated disruption while building resilience and thus facilitating their growth. Components of smart supply chain are being leveraged by several FMCG firms and these include advanced planning and scheduling where they use production and inventory data in real-time. They are also known to leverage the tremendous potential of augmented reality for all their activities associated with maintenance (Lin, Ieromonachou, & Sun, 2016). A smart supply chain is deemed to be something that is very holistic which moves over traditional logistics systems with regards to making an impact on the wider enterprise and ecosystem. A flexible system enables self-optimization of performance across a broader network, gain learning and selfadapt from unique scenarios in almost real-time or real-time while tackling the entire logistics network on their own (Lin et al., 2016).

Developing Resilience

Extant literature related to risk management within logistics and resilience has observed a transition over the last five year period (Bailey, 2016). It has been frequently deliberated within literature that there has been a dire necessity to make the shift from traditional approaches to managing risk wherein inherent challenges had to be confronted. At the same time, predicting some risks and its impact due to the complex environment that makes up logistic networks (Fiksel, 2015; Scholten, Sharkey Scott, & Fynes, 2014). There have been many remarkable studies (Pettit, Croxton, & Fiksel, 2013; Vilko, Ritala, & Edelmann, 2014), carried out within this domain, that highlighted the concept of resilience, while presenting the key constructs for building resilience within logistics networks. As a concept, resilience traditionally focused on varied aspects of managing risks. According to recent perceptions, it has turned out that resilience would make up a substantial block of developing resilience in the network (Ivanov, Tsipoulanidis, & Schönberger, 2019). When FMCG firms gain competitive advantage over their competitors by operating at a higher level, this would be in total contrast to other organizations that fail or ignore to bring in the aspect of resilience within their logistics operations.

In case end-to-end logistics networking costs are considered, it turns out to be a vital pre-requisite that plays a key role in developing resilience within logistics network. This is owing to the fact that it allows organizations to accurately weigh the impact from their strategies for logistics network (for example; selecting a location that allows manufacturing at very low rates) in tandem with costs associated with pertinent risks (Fast-forward, 2020). In the present day nevertheless, there is an absolute absence of overall transparency with regards to costs linked with logistics network that increases their risk exposure. For instance, it has been found that around 37 per cent of firms consider the costs that come up from risks emerging from specific locations (Fast-forward, 2020).

Harnessing the potential of technology within logistics network would be a multiyear, multi-technology initiative, in the aftermath of some specific disruptions like the present pandemic. Given the scenario, there have been several organizations that have increased their investments with regards to technology that bring in intelligence and autonomy across their logistics network (PWC, 2025). Intelligence, as well as autonomy is considered as vital aspects that allow resilience to be developed as it facilitates logistics networks to expect and promptly adapt themselves to disruptions of any kind or any inherent changes. According to research, it has been reported that around 47 per cent of FMCG firms have increased their investments with the goal of automating their processes while around 39 per cent of firms have made investments within robotics (Deloitte, 2021). Furthermore, AI and IoT are being perceived by organizations as substantial tools and it is now gaining momentum where more and more organizations are making technological investments in anticipation of handling any crisis in future. Nevertheless, investments with regards to certain technologies that are essential to develop resilience over a long-term period, such as control towers, which facilitate increased visibility and digital twins that extend support with regards to contingency planning, are expected to grow at a pace which is considerably slow, within other domains (Patsavellas, Kaur, & Salonitis, 2021). This has emerged as a gap that organizations are expected to surmount.

While FMCG firms have come up with many diverse steps to strengthen their logistics networks with a view to handle any risks and disruptions, there are certain firms that are developing their abilities from a wider context. In order to be prepared on the whole for future disruptions, it is recommended that FMCG firms focus more on each individual aspect with regards to developing resilience (Deloitte, 2020).

Conclusion

The rapidly altering market dynamics has modified consumer demand while presenting challenges for integrated logistic networks while altering some dynamics permanently, thus rendering it as new normal for the FMCG sector. The world over, tremendous opportunities have emerged for FMCG firms, which forces them to respond, recover and flourish. This opportunity is being harnessed by FMCG firms to understand the impact of market uncertainties over the period of a long-term, on the way they function, while concentrating on novel ways to handle uncertainties to maintain their competitive advantage on the basis of practices that are resilient.

Tutors India Assignment Writing Services

Tutors India offers exemplary assignment writing services that students can leverage during their academic pursuits. We offer assignment writing services for various subjects such as; management, human resources, economics, healthcare, and many more. We have experts across multiple domains with years of experience that are adept at providing you assignment writing services to help you acquire the upper edge in your educational endeavours. The assignment writing services that we offer are extensive, detailed, analytical and most important of all, timely. We guarantee timely delivery for all your assignment writing requirements while not focusing on quality. Gain the academic advantage that you have been vying for, contact us now!

References

- Bailey, K. (2016). An investigation into risk and vulnerability in the UK food supply network. Cardiff University. Retrieved from https://www.semanticscholar.org/paper/Aninvestigation-into-risk-and-vulnerability-in-theBailey/118a8c36623c9d7ce9b5dc2376a1d696ec12cf17

- Deloitte. (2020). Building Supply Chain Resilience beyond COVID-19. Retrieved from https://www2.deloitte.com/content/dam/Deloitte/ch/Documents/consumerbusiness/deloitte-ch-study-building-supply-chain-resilience-covid-19-2020.pdf

- Deloitte. (2021). Resilience in the FMCG & Retail Sector. Retrieved from https://www2.deloitte.com/content/dam/Deloitte/in/Documents/consumer-business/incb-resilience-in-the-FMCG-retail-sectors-noexp.pdf

- Dubeauclard, R., Kubik, K., & Nagali, V. (2015). How agile is your supply chain? McKinsey Quarterely, Published on April. Retrieved from https://www.mckinsey.de/~/media/McKinsey/Business Functions/Operations/Our Insights/How agile is your supply chain/How_agile_is_your_supply_chain.pdf

- Dubihlela, J., Chakabva, O., & Tengeh, R. (2021). A risk management framework for fast moving consumer goods retailers in South Africa. FORCE: Focus on Research in Contemporary Economics, 2(1), 4–40. Retrieved from https://www.forcejournal.org/index.php/force/article/view/21

- EY. (2020). Managing the impact of COVID-19 on India’s supply chains. Retrieved from https://assets.ey.com/content/dam/ey-sites/ey-com/en_in/topics/government-and-publicsector/2020/09/managing-the-impact-of-covid-19-on-india-supply-chains.pdf

- Fast-forward. (2020). Rethinking supply chain resilience for a post-COVID-19 world. Retrieved from https://www.capgemini.com/wp-content/uploads/2020/11/Fastforward_Report.pdf

- Fiksel, J. (2015). From risk to resilience. In Resilient by design (pp. 19–34). Springer. Retrieved from https://link.springer.com/chapter/10.5822/978-1-61091-588-5_2 Ivanov, D., Tsipoulanidis, A., & Schönberger, J. (2019). Supply Chain Risk Management and Resilience. https://doi.org/10.1007/978-3-319-94313-8_15

- Karthik, T. T., & Prasad, T. P. R. (2020). SWOT (Strength, Weakness, Opportunities and Threats) Analysis of Fast Moving Consumer Goods (FMCG) Industries in India. Shanlax International Journal of Commerce, 8(1), 92–100. Retrieved from https://www.researchgate.net/profile/Ramprasad-Tp2/publication/350877666_SWOT_Strength_Weakness_Opportunities_and_Threats_Ana lysis_of_Fast_Moving_Consumer_Goods_FMCG_Industries_in_India/links/6077ea3c8 81fa114b402d09e/SWOT-Strength-Weakness-Opportunities

- Kundu, J. (2020). Risk in Supply Chain Management and its solution. Retrieved from https://himhaldia.edu.in/wp-content/uploads/2020/journal_file/ijiparv2.pdf#page=52

- LeMay, S., Helms, M. M., Kimball, B., & McMahon, D. (2017). Supply chain management: the elusive concept and definition. The International Journal of Logistics Management, 28(4), 1425–1453. https://doi.org/10.1108/IJLM-10-2016-0232

- Lin, Y., Ieromonachou, P., & Sun, W. (2016). Smart manufacturing and supply chain management. 2016 International Conference on Logistics, Informatics and Service Sciences (LISS), 1–5. IEEE. https://doi.org/10.1109/LISS.2016.7854383

- Mckinsey & company. (2020). Future of retail operations: Winning in a digital era. Retrieved from https://www.mckinsey.com/~/media/McKinsey/Industries/Retail/Our Insights/Future of retail operations Winning in a digital era/McK_Retail-Ops2020_FullIssue-RGB-hyperlinks-011620.pdf

- khtar, A., Romli, A., Abdullateef, M., & Al-bashiri, H. (2019). Environmental risks in supply chain: recommendations and directions for future research. IOP Conference Series: Materials Science and Engineering, 551(1), 12034. IOP Publishing. Retrieved from https://iopscience.iop.org/article/10.1088/1757-899X/551/1/012034/meta

- Patil, P. (2016). An Overview of Indian FMCG Sector. PARIPEX - INDIAN JOURNAL OF RESEARCH, 5, 171–173. Retrieved from https://www.researchgate.net/publication/314216580_An_Overview_of_Indian_FMCG_ Sector

- atsavellas, J., Kaur, R., & Salonitis, K. (2021). Supply chain control towers: Technology push or market pull—An assessment tool. IET Collaborative Intelligent Manufacturing, 3(3), 290–302. https://doi.org/10.1049/cim2.12040

- Pettit, T. J., Croxton, K. L., & Fiksel, J. (2013). Ensuring Supply Chain Resilience: Development and Implementation of an Assessment Tool. Journal of Business Logistics, 34(1), 46–76. https://doi.org/10.1111/jbl.12009

- PWC. (2025). Connected and autonomous supply chain ecosystems 2025. Retrieved from https://www.pwc.de/de/digitale-transformation/connected-and-autonomous-supplychain-ecosystems-2025-web.pdf

- Scholten, K., Sharkey Scott, P., & Fynes, B. (2014). Mitigation processes – antecedents for building supply chain resilience. Supply Chain Management: An International Journal, 19(2), 211–228. https://doi.org/10.1108/SCM-06-2013-0191

- Sendil, M. (2015). Developing a successful and sustainable agile supply chain in alignment with business strategy for profitability. IOSR Journal of Business and Management, 17(5), 40–54. Retrieved from https://iosrjournals.org/iosr-jbm/papers/Vol17- issue5/Version-4/I017544054.pdf

- Shahbaz, M. S., RM, R. Z., Bin, M. F., & Rehman, F. (2017). What is Supply Chain Risk Management? A Review. Advanced Science Letters, 23(9), 9233–9238. https://doi.org/10.1166/asl.2017.10061

- Sharma, S. K., & Bhat, A. (2014). Supply chain risks: development of model and empirical evidence. International Journal of Applied Management Science, 6(1), 45. https://doi.org/10.1504/IJAMS.2014.059293

- Simchi Levi, D., Vassiladis, C., & Kyratzoglou, I. (2013). Making the right risk decisions to strengthen operations performance. PwC and the MIT Forum for Supply Chain Innovation. Retrieved from Supply chain and%0Arisk management%0AMaking the right risk decisions to%0Astrengthen operations performance

- Vilko, J., Ritala, P., & Edelmann, J. (2014). On uncertainty in supply chain risk management. The International Journal of Logistics Management, 25(1), 3–19. https://doi.org/10.1108/IJLM-10-2012-0126